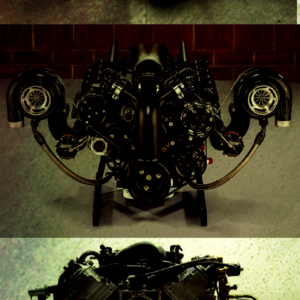

“BIG HOSS” 427 STROKER LS DART BLOCK FED HEADS RACE READY STUDDED TURBO – LONG BLOCK ONLY 2000HP READY!! WE PULLED OUT ALL THE STOPS HERE AND ADDED FULL CERAKOTE BLOCK, HEADS, PISTONS, AND CHAMBERS

$28,888.00

WARNING!! THIS IS A SUPER HIGH PERFORMANCE ENGINE! SIDE EFFECTS INCLUDE WHIPLASH, AND THE ABILITY TO MAKE YOUR PASSENGERS PISS THEIR PANTS. NOT FOR USE IN INCLEMENT WEATHER.

!!NOW WITH THE ADDITION OF FULL CERAKOTE!!

COMES AS A LONG BLOCK, DIFFERENT OPTIONS AVAILABLE FOR COVERS OR TURN KEY PACKAGES

THIS IS BUILD FOR TURBOCHARGER, FOR NA APPLICATION SEE MAX EFFORT NA 427

FRANKENSTEIN ENGINE DYNAMICS CYLINDER HEADS FULLY BUILT

!! FULL CERAKOTE FOR PISTONS, BLOCK, HEADS, CHAMBERS !!

DIFFERENT CAMSHAFT OPTIONS AVAILABLE FOR EXAMPLE:

BTR 400+ BIG TWIN TURBO CAMSHAFT

246/26X .619″/.619″ 115 LSA

INTAKE LOBE LIFT @ TDC: 0.07821

The new BTR Big Twin Turbo cam was designed for use on 82mm or larger twin turbo setups or single 102-106mm turbos in 400-427 cubic inch combos. This cam was designed for use in high horsepower,max effort applications looking for more power at higher rpm , and offers an ultra-aggressive idle. This cam has the potential to push a 400″ engine well over 2000 rwhp and into the 6 second range in the quarter mile. This cam uses ultra stable lobes designed in house and Spintron tested for higher RPM potential, and was designed to be extremely durable at high rpm when combined with a lightweight valvetrain.

Due to higher rpm potential combined with greater cylinder pressure from boost we recommend the use of our SK703 spring kits, larger diameter hardened pushrods, and a quality lifter such as a Johnson ST2116LSR or ST2126LSR.

OR FOR EXAMPLE:

BTR 400+ SMALL TWIN TURBO CAMSHAFT

237/25X .619″/.619″ 117 LSA

INTAKE LOBE LIFT @ TDC: 0.05840

The new BTR Small Twin Turbo cam was designed for use with smaller twin 66-76 mm setups or up to a single 94mm turbo in 388-427 cubic inch combos. This cam is recommended for street/strip type applications looking for more power and rpm , and offers an aggressive idle. This cam uses ultra stable lobes for higher RPM potential, and was designed to be extremely durable at high rpm when combined with a lightweight valvetrain.

Due to higher rpm potential combined with greater cylinder pressure from boost we recommend the use of our SK703 spring kits and larger diameter hardened pushrods along with a quality lifter such as a Johnson ST2116LSR or ST2126LSR.

OR FOR TRUCK APPLICATION:

BTR 400+ TRUCK LS TURBO CAMSHAFT

225/24X, .629″/.629″, 116 LSA

BTR is proud to introduce this new addition to our already impressive lineup of Gen III/IV turbo camshafts. The new 400+TruckTurbo camshaft was designed for those customers running a stroker 400-416 cubic inch turbo combination . Designed to be used with smaller twins or single turbos in the 70-76mm range for use in mild towing or daily driven applications. This cam will help your stroker turbo combination produce additional horsepower throughout the curve, while delivering excellent street manners. As with all BTR offerings, these cams were designed to help achieve the highest overall power curve while also maintaining strict valvetrain stability and durability standards.

The use of BTR dual platinum spring kits is required due to high valve lift and increased rpm potential.

We also recommend the use of hardened pushrods in power adder applications.

May require a aftermarket converter in some truck applications.

The use of E85 or higher octane fuel may be required with the addition of higher boost pressure.

427-430 CUBIC INCH

DART AFTERMARKET BLOCK

ARP STUDDED TOP AND BOTTOM END

BILLET CAPS

ALL BIG 3 FORCED INDUCTION ENGINES REQUIRE TOP AND BOTTOM END STUDDING AND FORGED ROTATING ASSEMBLY/PISTONS

CNC MOTORSPORT ROTATING ASSEMBLY-BALANCED

CALLIES CRANKSHAFT

BOOSTLINE RODS

JE PISTONS

BTR PLATINUM SPRINGS

BTR RETAINERS, KEEPERS, HAT SEALS

JOHNSON OILING LIFTERS

ARP TOP AND BOTTOM STUDDED

KING/CLEVITE BEARINGS RACE COATED

.080 CHROMOLY PUSHRODS FROM BTR

SHAFT ROCKERS

ADDITIONAL HEAD BOLT ROW FOR ADDED CLAMPING FORCE TO REDUCE HEAD LIFT UNDER BOOST

PREMIUM VALVES

3 ANGLE VALVE SEATS

Description

All remanufactured engines are Carefully Assembled. Blocks, heads, rods, crankshafts and camshafts are thoroughly cleaned before assembly to remove all contaminants which can lead to early component and engine failure. All remanufactured engines are Carefully Assembled. Blocks, heads, rods, crankshafts and camshafts are thoroughly cleaned before assembly to remove all contaminants which can lead to early component and engine failure. |

Crankshafts are precision machined to exact tolerances, polished & magnafluxed, then inspected by our quality control department. These are matched with new premium bearings for long life. Crankshafts are precision machined to exact tolerances, polished & magnafluxed, then inspected by our quality control department. These are matched with new premium bearings for long life. |

Cylinder Heads are resurfaced to assure a proper sealing surface with the block and a finish compatible with today’s new gasket materials. New valves, springs, rockers, retainers, locks, seals, and if needed seats and guides, are installed. Valve height is miked and every head is vacuum tested to assure correct valve seating. Every cylinder head recieves a premium 3-angle valve job. |

Cylinder Blocks are magnetic particle inspected for cracks or imperfections. Cylinders are bored and honed and inspected to precise tolerances. Torque plate honing is performed on specific engines to eliminate cylinder head distortion after the head is bolted and torqued to the block. This process eliminates a major cause of engine blow-by. Block surfaces are machined and then inspected to ensure proper finish. |

Camshafts are inspected and precisely machined to provide correct lift. We only use new camshafts, lifters, and camshaft bearings in all our assemblies. |

Connecting Rods are machined to O.E.M. specifications and honed to the standard diameter of original equipment for even distribution of stress on the bearings. New bushings are installed and machined in all bushed rods. Every rod is carefully inspected for bend and twist as are all remanufactured parts. |

Remanufacturing |

New Parts |

Reviews

There are no reviews yet.